SUPERVISION

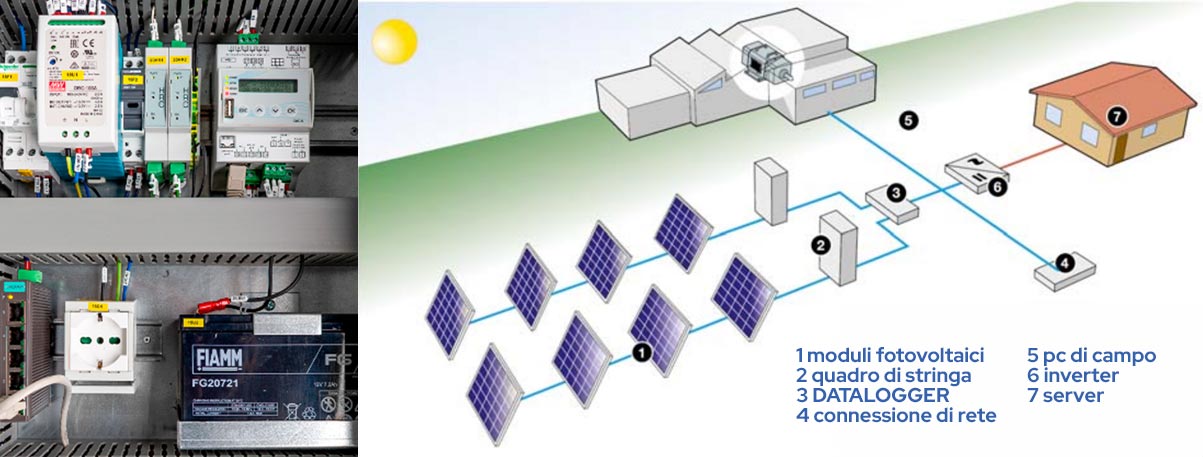

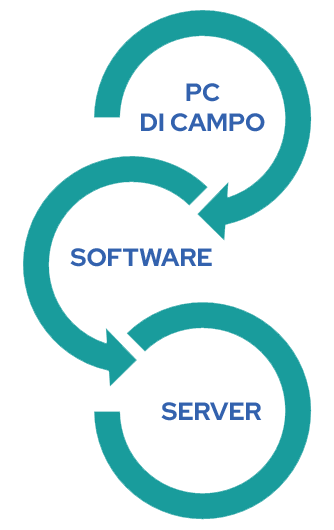

PLC programming and association with industrial supervisory control systems on Windows PCs (SCADA) allow us to offer ourselves as a partner for all advanced automation applications.

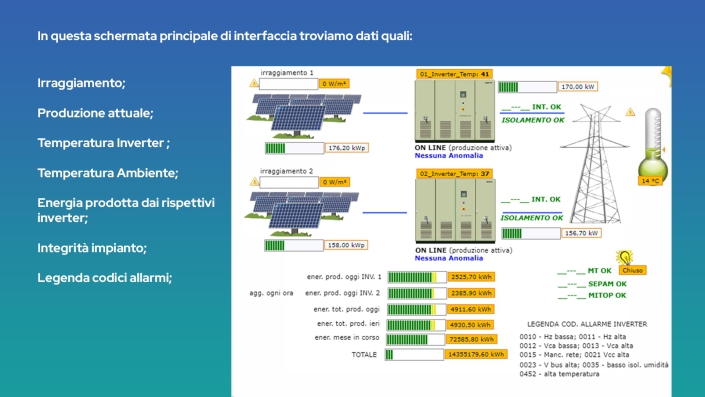

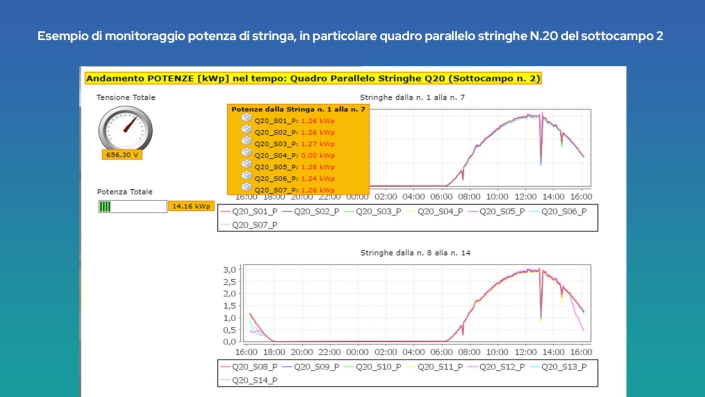

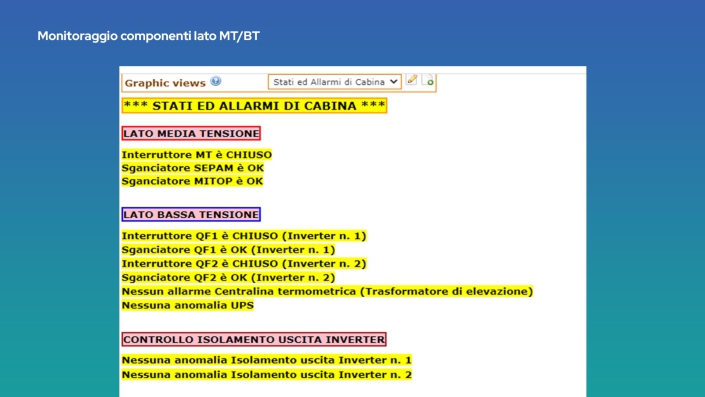

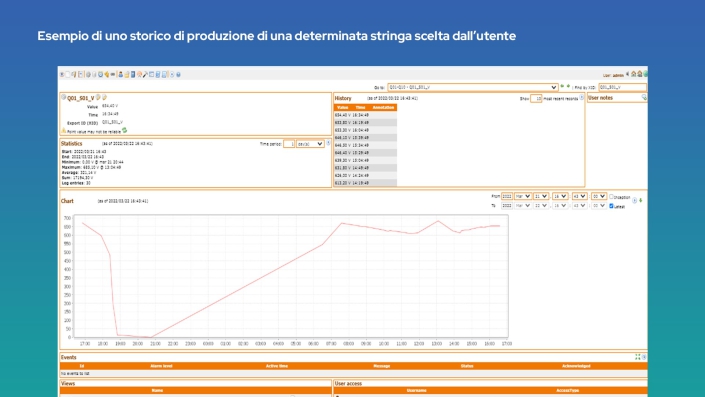

Through applications of this type, the operating parameters of complex machinery and plants can be controlled from a single operator station in a graphical environment with immediacy and simplicity.

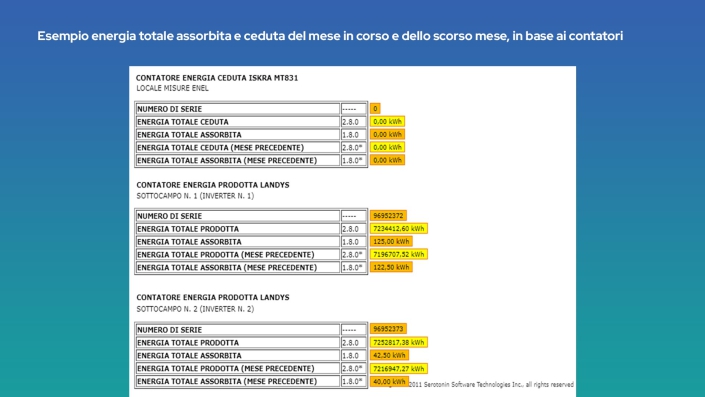

The quantities that can typically be managed are:

- Setting times and displacements

- Complex operations

- Special cycles

- Diagnostics for alarms and scheduled maintenance with the possibility of remote control and assistance

- Production and inventory reports

- Calculation of product costs taking into account downtime and other variables.